ENREM offers advanced, effective, and integrated solutions, and high quality services. Our greatest asset is the comprehensive nature of the services we provide, starting from pre-repair diagnostics with the assessment of the technical condition of the elements, through the preparation and production of the replaced and overhauled components, their machining, carrying out overhaul and modernisation works, all the way to the preparation of facilities for commissioning, preparation of documentation, and post-repair recommendations. In an effort to complement the comprehensiveness of our maintenance services, ENREM – Połaniec established a specialised technological office, in which the main objective is to support the departments of production preparation and subcontracting in the completing of services maintaining the highest quality, safety at work, and environmental protection.

Our experts and engineers cooperate with the leading academic centres in the country: Warsaw University of Technology, Radom University of Technology, Institute of Non-Ferrous Metals at AGH University of Science and Technology, Instytut Spawalnictwa (Welding Institute) in Gliwice, the Institute of Power Engineering.

- overhauls and modernisation of boilers together with auxiliary equipment in the boiler room

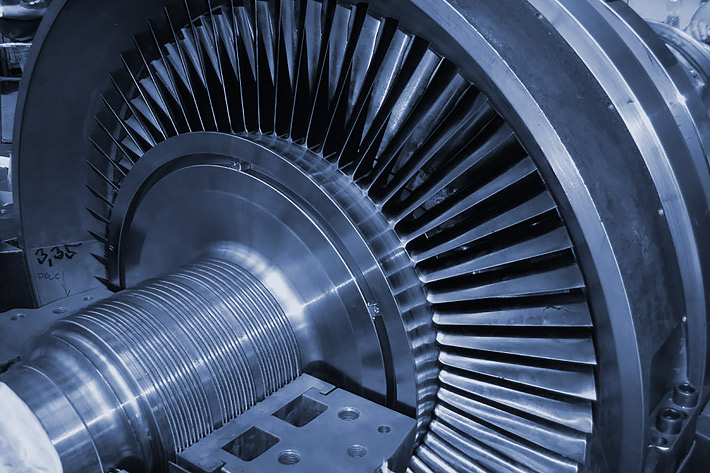

- overhauls and modernisation of turbine sets together with equipment in the plant room

- installation of piping systems and industrial systems

- manufacturing of spare parts for boilers, steel structures, pressure, and non-pressure vessels

- prefabrication of pipeline elements

- special non-destructive, destructive, metallographic, and technical survey reports

- pressure parts – boiler drums, screens, primary steam superheaters, secondary steam superheaters, water superheaters, steam pipelines

- auxiliary equipment – electrostatic precipitators, coal pulverisers, coal feeders, air heaters, slag traps, powdered-fuel burners, ignition burners, air fans, flue gas fans, mill fans, shut-off dampers and control flaps, coal feeders, electrostatic precipitators, and fittings

- auxiliary systems – air and flue gas ducts, ducts for pulverised coal-air mixture, ignition systems, carburising systems, ash removal and desulfurisation systems, biomass feeding systems, deslagging systems, heavy oil plants, water preparation systems

- oad-bearing structures of boilers

- TURBINES: steam turbines, gas turbines, generators, cooling systems, oil systems, condensation systems, vacuum systems, control systems

- FITTINGS, PIPELINES, AND EXCHANGERS: high-, medium- and low-pressure fittings, including regeneration of housings, high- and low-pressure heaters, reduction and cooling stations, pressure vessels, pipelines

- We carry out assembling of pipelines and fittings for systems carrying water, steam, oil, chemically aggressive media, and others. We have experience in the completion of orders, both in Poland and abroad. We carry out works both on the existing facilities and on new power units under construction.

- We have experienced teams of highly qualified fitters and welders with UDT and TÜV qualifications for performing TIG, MAG, and covered electrode welding. We specialise in welding of carbon and alloy steels designed, among other things, to work in elevated temperatures and aggressive environments. We work closely with our welding department and the laboratory for destructive and non-destructive material testing, thanks to which we are capable of welding materials that require the use of complicated welding technologies.

- Office building with social facilities – a separate area for the technical control department with a laboratory, a tool-room with the electrician’s workshop, functionally connected to the production floor

- Production floor – two independent bays with the total area of 3,000m2, two 25/5T cranes and two 2-3T cranes, a rolling mill, bending machines, plasma cutters

- Coating preparation floor – a shot-blasting chamber 17 x 5 m, a paint shop with heating and ventilation units, occupying the area of 500 m2, featuring an 8T overhead travelling crane

- Storage facilities a warehouse building occupying the area of 400m2, a roofed shelter for steel products occupying the area of 1000m2, featuring a 10T overhead travelling crane storage and intermediate storage yards occupying the area of 2000m2